EMULSIFIER SERIES

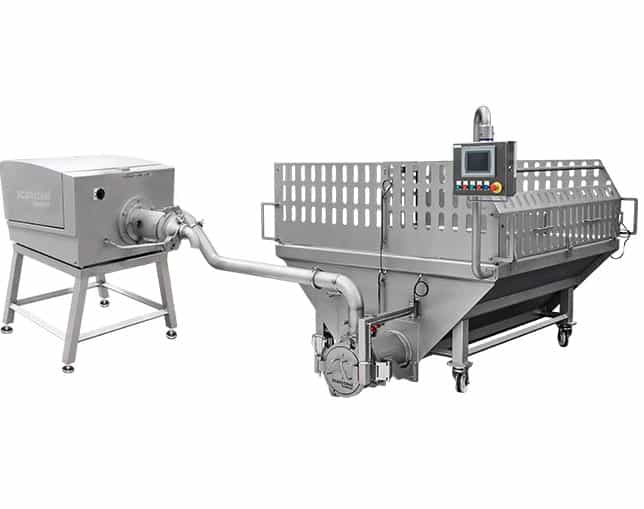

positioned so either one or two mixers can discharge into the infeed

hopper of the ContiPump

250.

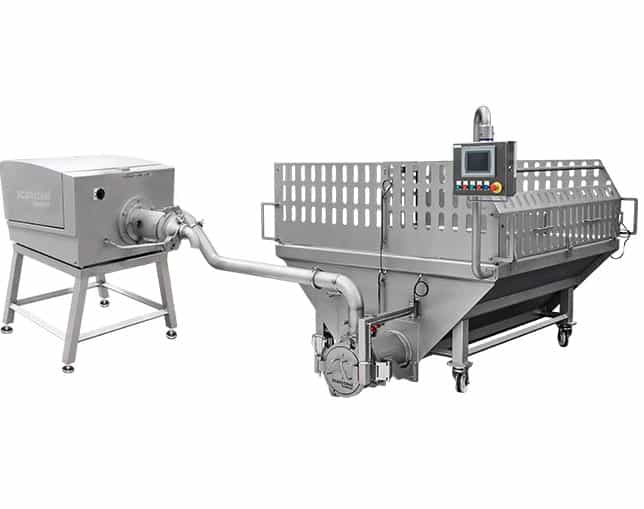

QuadroCut 225

be coming soon..

be coming soon..

cabinet work is manufactured in stainless

steel AISI 304.

intervals.

MC 250

be coming soon..

be coming soon..

be coming soon..

gear box dramatically

increases life time of

gear box.

scansteel foodtech® emulsifier series is Danish quality equipment conceived, engineered and manufactured in Denmark. Our emulsifier series is highly reliable, including high – and consistently performing emulsifiers designed for uniform product quality. The functionality of our emulsifier series ensures low running costs just as safe and easy operation.

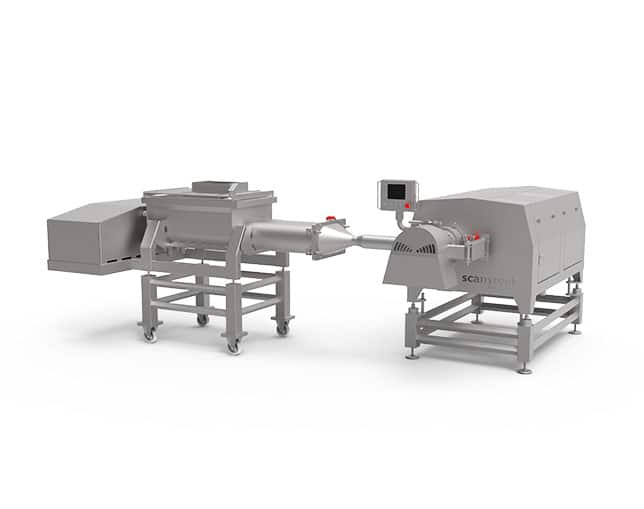

scanEmul 175 Series

If you want to know more about scansteel foodtech® scanEmul 175 Series, Click here

scansteel foodtech® scanEmul 175

– Hopper Fed

scansteel foodtech® scanEmul 175

– Pump Fed

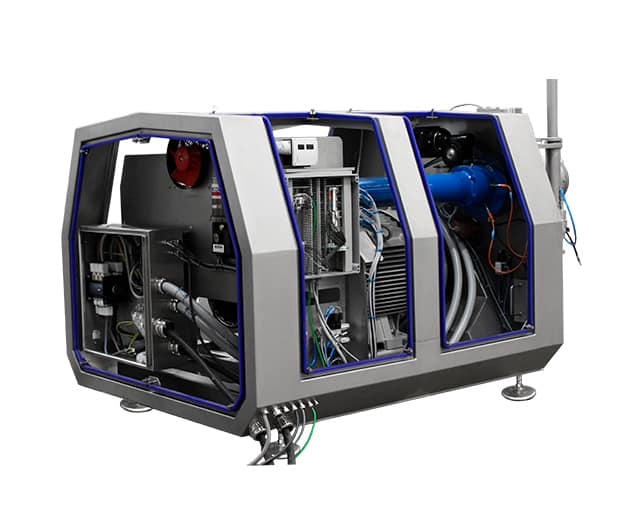

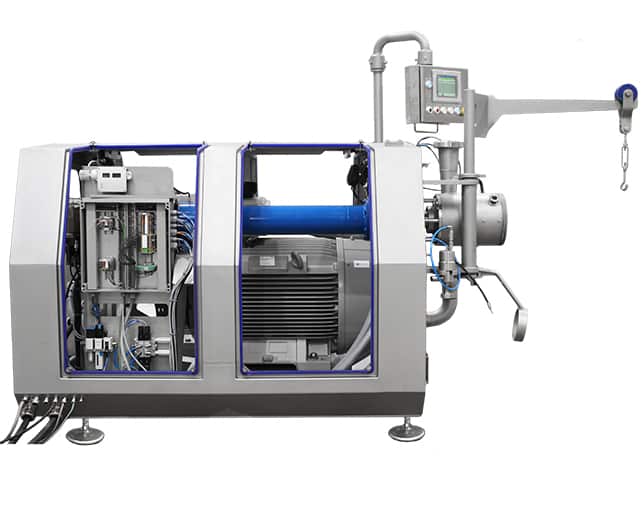

QuadroCut(Vac) 225 Series

If you want to know more about scansteel foodtech® QuadroCut(Vac) 225 Series, Click here

scansteel foodtech®

QuadroCut 225

scansteel foodtech®

QuadroCut Vac 225

scansteel foodtech®

QuadroCut Vac 225 – TemBi

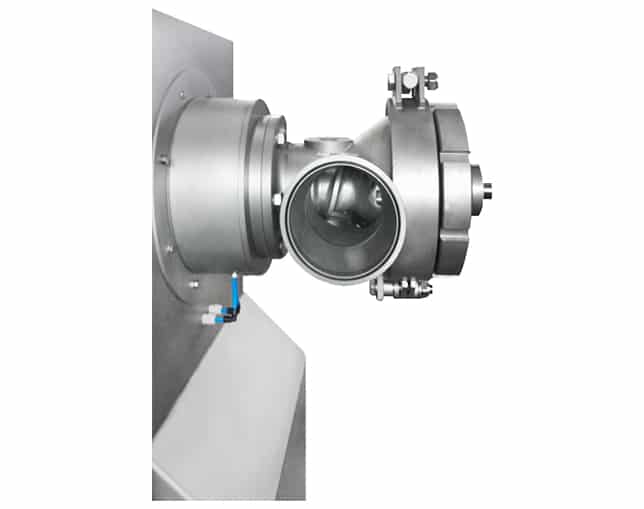

QuadroCut(Vac) 225 Ultra-Flexible Knife System Set-up

processors’ workshop by trained technicians. As such, the only thing the machine operators mustdo is

to replace the knife cassette at agreed intervals.

Knife Set Combinations:

- QuadroCut:

- TrippleCut:

- DoubleCut:

4 knives – 3 hole plates

3 knives – 2 hole plates

2 knives – 1 hole plate

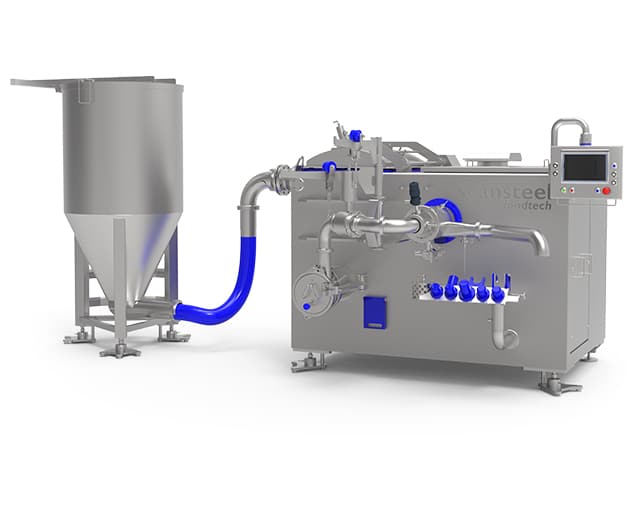

MicroCutter Series

If you want to know more about scansteel foodtech® MicroCutter Series, Click here

scansteel foodtech®

MicroCutter – Pump fed

scansteel foodtech®

MicroCutter – Hopper fed

scansteel foodtech®

MicroCutter – Screw hopper fed

MicroCutter Knife System Set-up

Knife Set:

1 hole plate =

2 hole plates =

3 hole plates =

1 (one) cutting edge against hole plate.

3 (three) cutting edges against hole plates.

5 (five) cutting edges against hole plates. With the wide selection of knives and hole plates, the scansteel foodtech MC 250 & MC 300 emulsifiers ensure you get the final emulsion/final product quality you require.