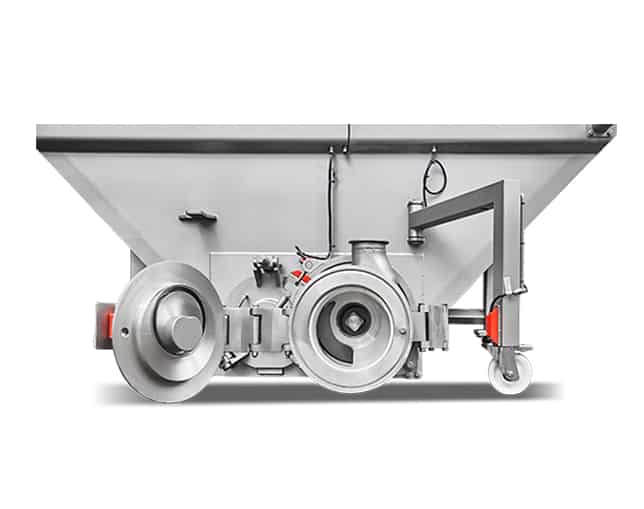

ContiPump 250/500 L - 10,000 L

disassembly.

ContiPump 250/500 L - 10.000 L

not limited to, pet food premixes being fed into an emulsifier as well as for various buffer/

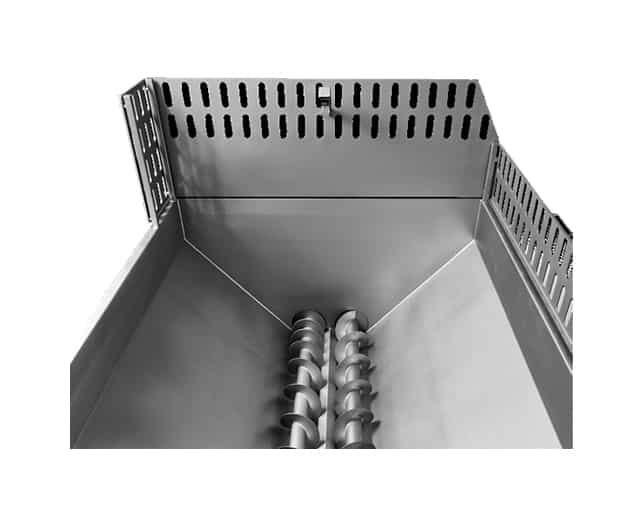

storage/silo applications. The buffer hopper comes in two versions: a single feeding screw

or a twin screw hopper, where one screw feeds/drives the ContiPump and the other prevents/

limits bridge building.

ContiPump 4000/250 Twin Screw

The scansteel foodtech® ContiPump series has been designed in such a way that the unit can function as a stand alone pump or, as shown above, can be designed to fully be integrated as part of an integrated solution with the scansteel foodtech® ContiPump and the scansteel foodtech® mixer series. In order to secure full hygiene solutions as well as having full access to both the mixer(s) and ContiPump for inspection/maintenance. The scansteel foodtech® ContiPumps can be placed on a “rail system” which makes it fully possible for a person to separate the ContiPump and mixer. At the same time, during production, the ContiPump is secure in “running position” in such a way that the ContiPump cannot be moved.

scansteel foodtech® ContiPump series comes in many different infeed hopper designs. Below shows a ContiPump 250 being fed by a scansteel foodtech Mixer/Grinder for pet food snack manufacturing.

ContiPump Solution for Pet Food

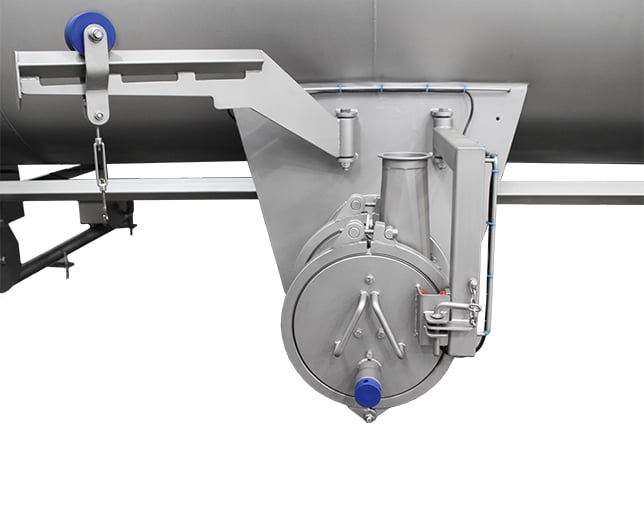

Top view of the rotation wing.

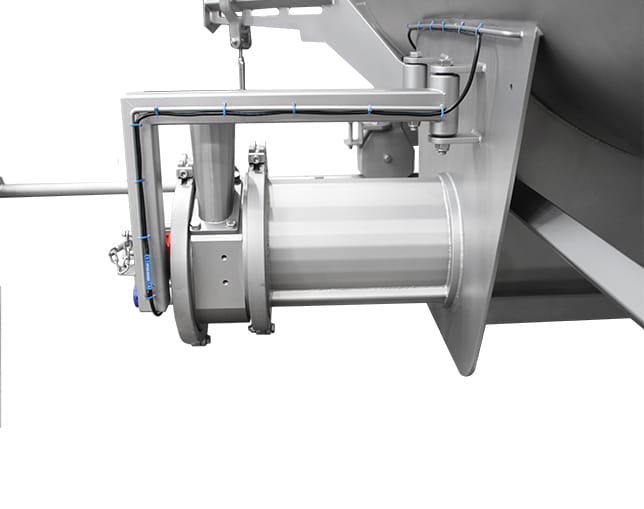

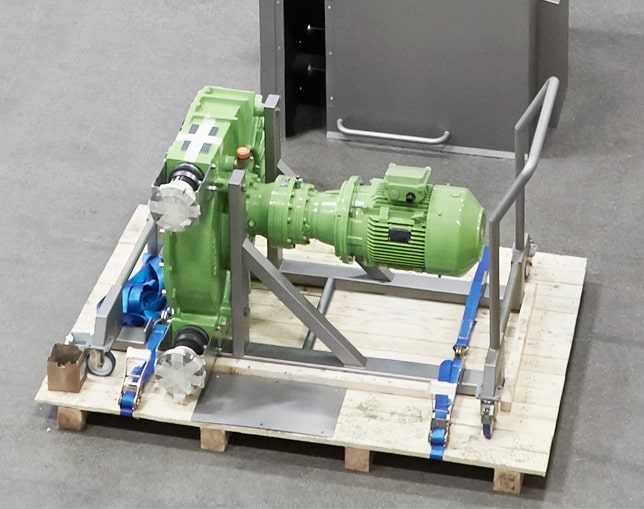

Snake Pump without cabinet.

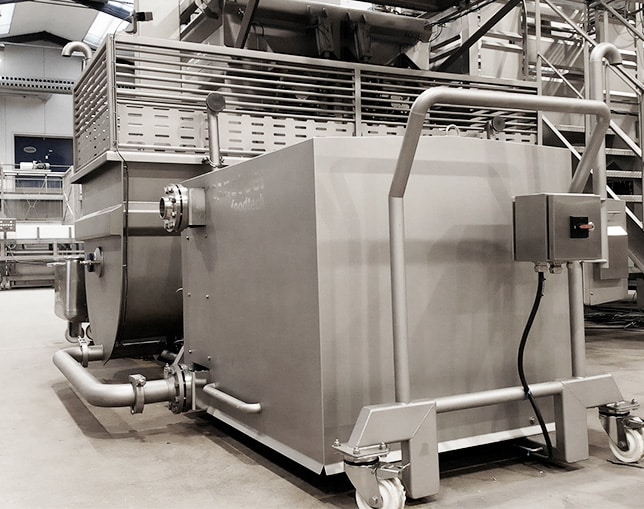

Fully assembled Snake Pump.

Video of rotating wing in Contipump.